Pneumatic rotary actuator by Friedemann Wagner

rotary actuator compactly summarized

Pneumatic rotary indexing tables are used in automation and processing applications in which a workpiece is brought into an exact position for further processing after a rotary movement; a separate position is generally used for loading and unloading. Typical applications can be found across all industries in:

- Manufacturing and assembly processes

- Packaging processes

- Inspection and testing applications

Alternatively, a pneumatic rotary indexing table is also used for classic material handling / material transport in confined spaces or for turning and rotating a workpiece.

Animation: technical principle of rotary indexers RSE-6 and RSE-9

Animation: technical principle of rotary indexers RSE-3 and RSE-4

Animation: technical principle of manually driven rotary indexer RSE-6-M

Downloads

NOTE: OUR DOWNLOADS ARE MAINLY AVAILABLE AS PDF FILES. YOU WILL NEED THE LATEST ADOBE ACROBAT READER TO READING THEM.

rotary indexing tables

Technical data, the 3D model as well as links to the brochure and operating instructions can be found directly in the product selected below.

Further information can be found in the central download area , under the FAQ section, our blogs or our YouTube channel.

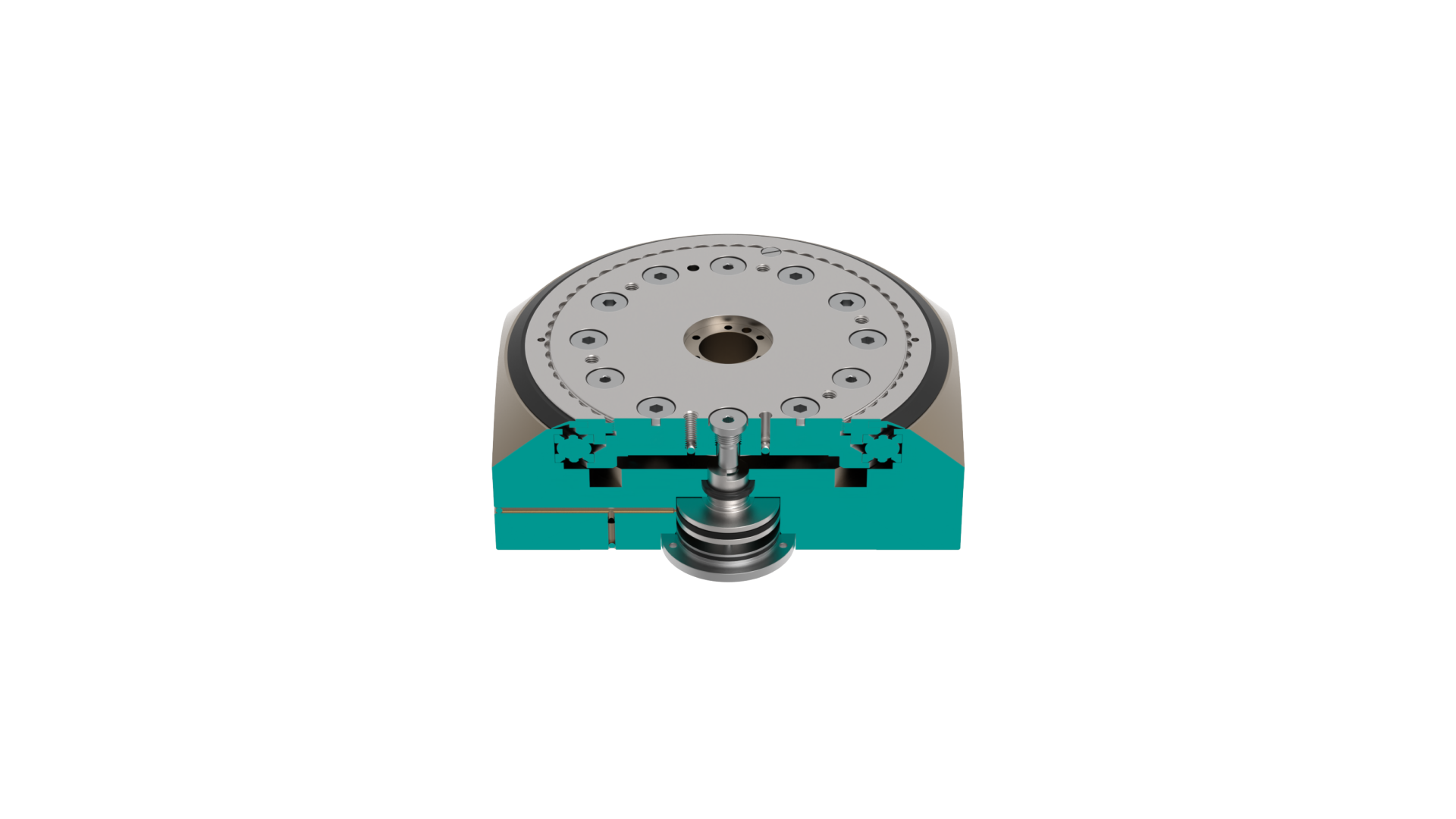

Technical principle of the rotary indexing tables from Friedemann Wagner GmbH

A pneumatic rotary indexing table operates based on compressed air. It is controlled by a valve or valve terminal. By opening and closing the valve, the compressed air is supplied or released. The compressed air moves a piston designed as a rack. This rack is connected to the table during forward travel and ensures that the plate rotates. The drive is disengaged as soon as the table reaches its end stop. The table is locked in this end position. This ensures a stable position for further processing of the workpiece. The locking mechanism can be monitored by a sensor to ensure that the table is correctly positioned. After locking, the rack returns to its starting position, ready for the next cycle. Unlike a rotary actuator, a rotary indexing table continues to rotate after stopping, while a rotary actuator pivots back. From a mechanical perspective, the distance traveled by the rack determines the so-called "partition". The longer the rack moves with the drive engaged, the greater the angle of rotation to the end position. The travel can be limited, for example, by spacers on the rack. The pitch is usually specified numerically: Partition 4 means a division into 4 x 90° angles (360/4 = 90). However, from a physical perspective, this means that some partitions (e.g., 180°) are structurally impossible because the required travel of the rack exceeds the dimensions of the table. This is the reason why RSE-6 and RSE-9 are only available from pitch 4 upwards.

This simple mechanical operation allows the pneumatic rotary indexing table to offer fast movement with precise

positioning in various industrial applications.

Benefits of rotary indexing tables by Friedemann Wagner GmbH

Friedemann Wagner GmbH is manufacturer of pneumatic rotary indexing tables since 1979 and has continuously optimized them based on user feedback.

High repeatability and durable products are reliable components for numerous customized rotary indexing tables (OEM) as well as for the standard range. The standard range is available from stock and includes 4 different sizes of pneumatic rotary indexing tables and one size of a manual rotary indexing table.

In addition to various directions of rotation and partitions a comprehensive range of accessories (sensors, conversion kits, screw-in columns, etc.) is also available.

Key product benefits of our rotary indexing tables:

All Wagner rotary indexing tables can be controlled for rotation and locking with one (!) valve – this saves resources, space, energy and control effort.

All pneumatically driven rotary indexing tables are fitted with hydraulic damping as standard. The RSE-6 and RSE-9 sizes can also be ordered with a low-wear pneumatic damper as an option.

Rotary indexing tables of sizes RSE-3 and RSE-4 can be converted by the customer in the direction of rotation and can also be ordered or operated in pendulum mode.

Different pitches are available ex works in the 4 sizes. Even odd pitches (e.g. pitch 7 or pitch 5) can be achieved with the RSE-6 and RSE-9 series rotary indexing tables!

The operation can be carried out by pure control (timer). To optimize the cycle, we recommend using the sensors offered as accessories!

Special version: manual rotary indexing table

RSE-6-M is a manual rotary indexing table for hybrid or partially automated workplaces. In these applications, the operating personnel determine the speed - the table automatically engages and locks in the end position after manual rotation. Since the unlocking is done with a simple 3/2-way valve (button, pedal, etc.), there is no need for extensive safety controls in the design. This saves costs and resources and enables quick implementation. The table can be converted by the customer in terms of division and direction of rotation, but does not have any damping.

We look forward to hearing from you

Personal advice

Friedemann Wagner GmbH

Robert-Bosch-Str. 5

D-78559 Gosheim

+49 (0) 7426 / 949 00 -0

+49 (0) 7426 / 949 00 -9

Write an email