Handling technology and automation technology at Friedemann Wagner

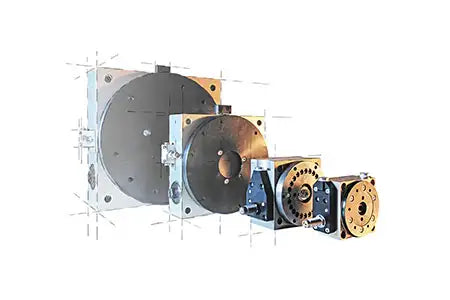

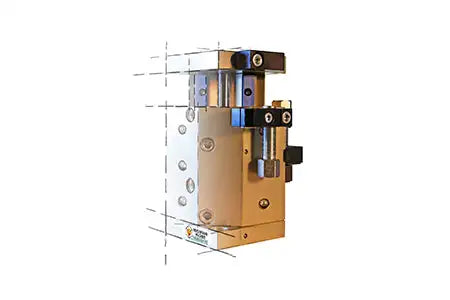

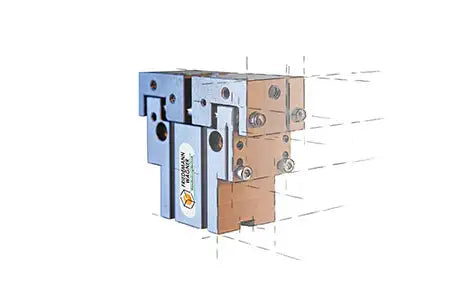

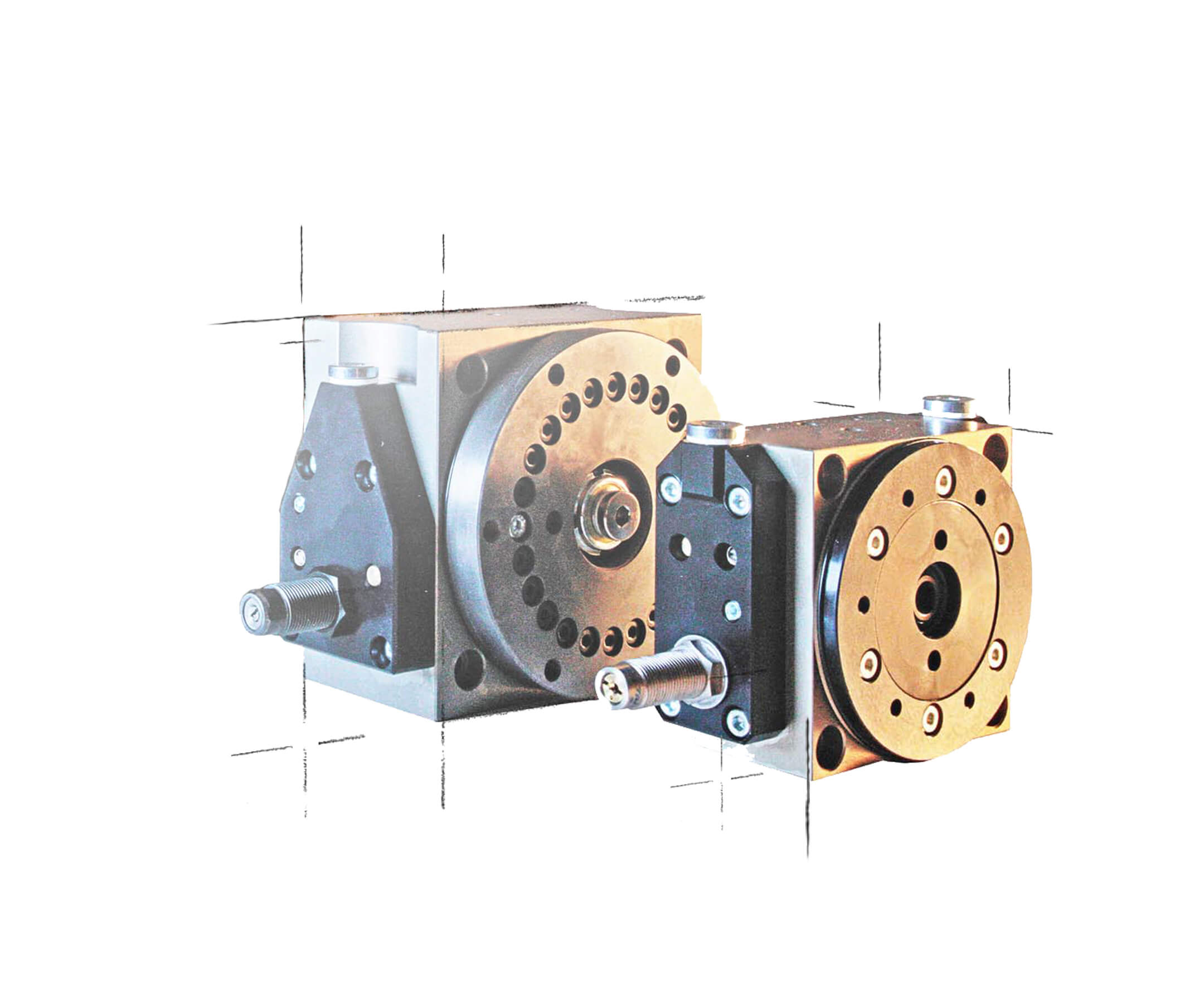

Since our foundation in 1979, we at Friedemann Wagner have been successfully manufacturing high-precision swivel drives and rotary indexing tables, as well as lifting units, linear units, parallel grippers and accessories at our Gosheim site in Württemberg.

Repeatability in the hundredths range ensures process reliability, minimizes adjustment effort and avoids unnecessary and costly production interruptions later on. All solutions are characterized by robustness and reliability. Extensive tests and years of use of Friedemann Wagner by our satisfied customers prove this.

Our product overview provides valuable details about our various service areas. Our range of services is summarized especially for you in this document.

Special design features allow use even in harsh industrial environments or difficult applications. Air feedthroughs and signal feedthroughs are available as options. An extensive range of accessories rounds off the scope of delivery of the automation technology pneumatic units.

All products are designed, manufactured and assembled in-house.

This corresponds to the Friedemann Wagner philosophy, enables customer-specific modifications and brings flexibility for our users. We meet the highest demands of our well-known customers every day - both technically and qualitatively. 40 years of market knowledge testify to a wealth of experience. You too can benefit from this.

Your opinion is important for us

Our references

“The Wagner slewing drives perform reliably. Since Friedemann Wagner as a manufacturer offers the overhaul or refurbishment of units, we are happy to use them as part of preventive maintenance and servicing. The modules are designed to be robust and durable - simply disposing of them would be a waste. Reconditioning has no disadvantages in further use, preserves value and is Swabian sustainability in practice on both sides.”

Jörg Jarwitz | Team leader spare parts management TPM | Roto Frank Fenster- und Türtechnologie GmbH

“You know, the Wagner modules are easy. Select them, buy them and install them, and then you can “hide them completely” thanks to their excellent quality. The modules run and run and do their job reliably.”

Ruedi Schlumpf | Managing Director Schlumpf Industrieprodukte GmbH

“The work result of the automation application is mainly dependent on the rotary indexing table.

It is a positive surprise for me how amazingly precise the manual rotary indexing table fulfills its task.”

Udo Jakobs | Managing Director Fa. Jakobs Technik

“Our customer has the following problem with an almost new rotary indexing table (19 years old):The rotary movement occurs at connection A - at B the locking bolt goes in - and comes out again as soon as the pressure drops. ‘Note: the rotary indexing table in question has been overhauled in wear parts and fitted with new seals, among other things!”

Peter Krista | Managing Director Aramis Maschinenbau GmbH & Co.KG

Family business

Since 1979

“As a family business and niche manufacturer with our own design, we offer the market pneumatic modules: precise, repeatable and durable.these properties are the building blocks for reliable function, avoid production downtime and ensure customer satisfaction and value retention.quality that has been moving since 1979!”

Andreas Wagner | Managing Director in second generation

Produced by Regio TV

We look forward to hearing from you

Personal advice

Friedemann Wagner GmbH

Robert-Bosch-Str. 5

D-78559 Gosheim

+49 (0) 7426 / 949 00 -0

+49 (0) 7426 / 949 00 -9

Write an email