Compact, well-thought-out units based on a practical modular system

Our products impress with precision and durability , as well as repeatability for intended use in automation.

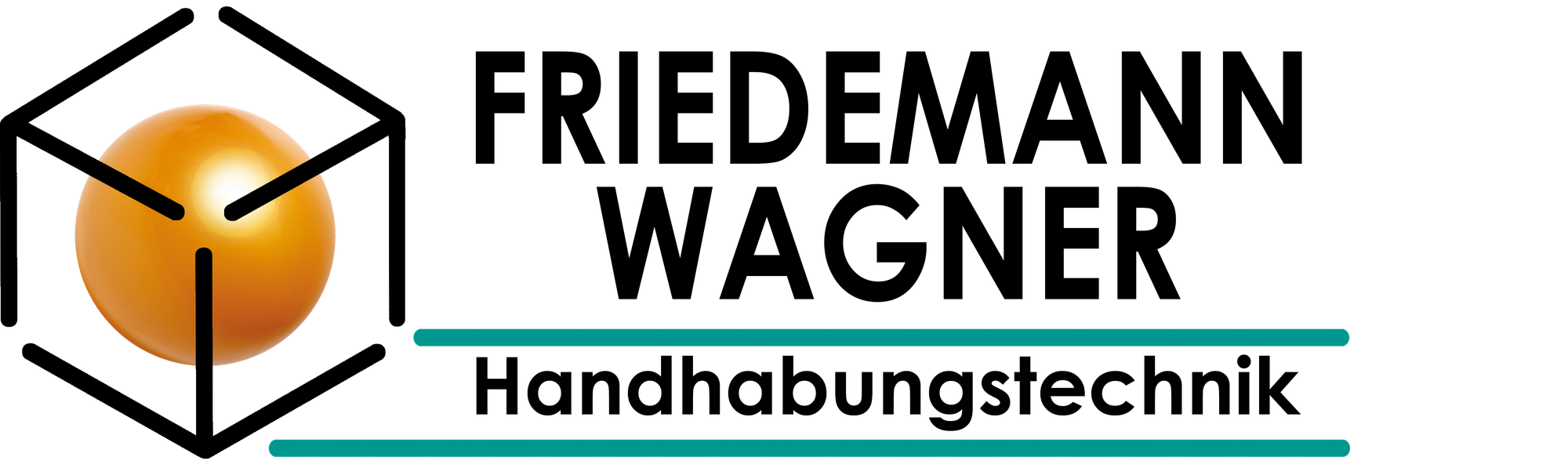

Rotary switching units

- Integrated throttle for adjusting the plate speed

- Various versions and sizes up to 70 kg clamping weight and 30 Nm torque

- Hydraulic damping included

- Wear-free pneumatic or hydraulic damping

- Pitches 2 to 24, odd pitches available for RSE-6 and RSE-9

- Direction of rotation right or left, with RSE-3 and RSE-4 alternatively pendulum

- Mounting for initiator for end position query

- Precisely fitting, backlash-free centering system for installation without drilling or pinning

- Fixed center hole for feedthrough (energy) or assembly

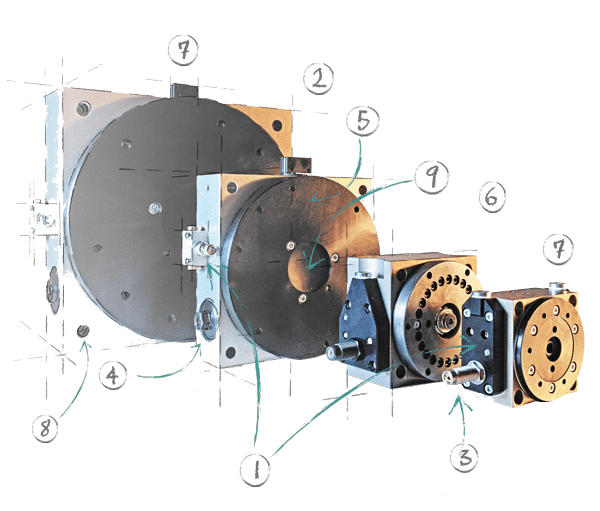

Swivel units

- External stops on ring surfaces for high repeatability and full force of the pistons in the end position

- Stop screws for stepless adjustment up to 190° (+/-95° around the center position)

- Air and signal feedthroughs available as variants

- Patented system for accommodating the proximity switch in the stop screw

- C-slots for accommodating magnetic field sensors

- All connections and interference dimensions on one side

- Mounting for hydraulic dampers for high mass moments of inertia up to 64200 kgcm2

- Grid dimension for a precise, backlash-free centering system for installation without drilling or pinning

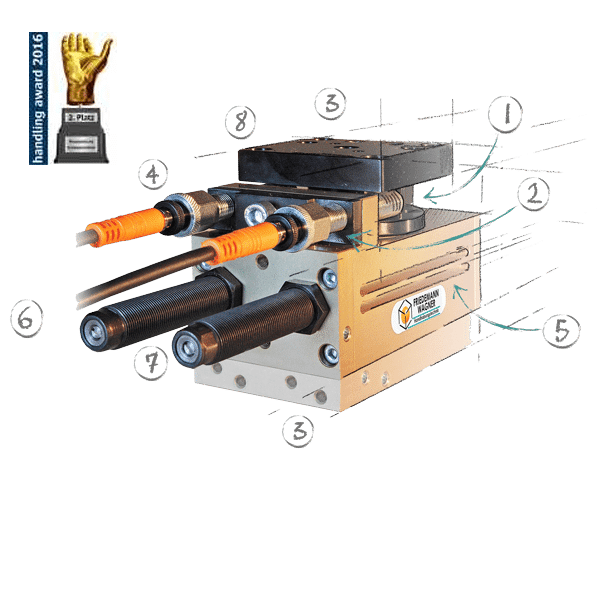

Lifting units

- External stops on ring surfaces for high repeatability

- Stop screws for stepless adjustment of the stroke

- Patented system for accommodating the proximity switch in the stop screw

- Various versions up to 470 N impact force and stroke lengths up to 100mm

- Mounting of hydraulic dampers for high masses

- Grid dimension for a precise, backlash-free centering system for installation without drilling or pinning

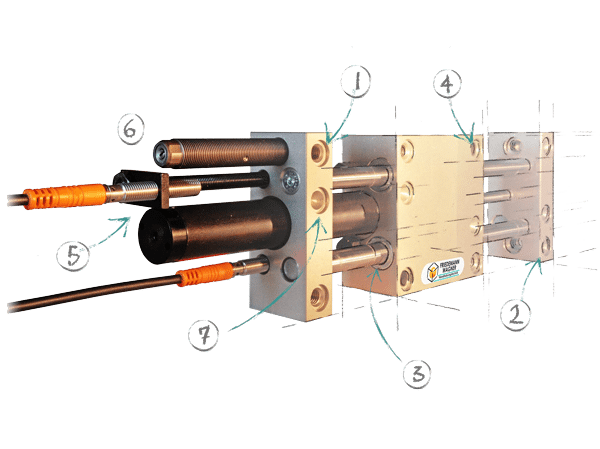

Linear units

- Various versions from 20 to 500 mm stroke for push and gantry operation

- Impact force up to 440 N with accuracies between +/-0.01 mm and +/-0.03 mm

- Different bearing types for guiding up to 70 kg maximum payload

- Grid dimension for a precise, backlash-free centering system for installation without drilling or pinning

- Mounting for inductive proximity switches

- Mount for hydraulic shock absorbers

- Versions for mounting external, hardened stops

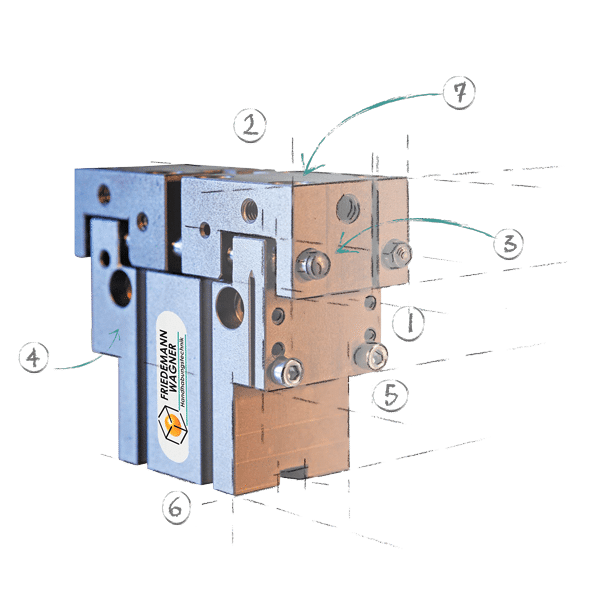

(Parallel) gripping units

- Various sizes from 2 to 15mm stroke per jaw and up to 7.2 kg workpiece weight

- High repeatability of +/- 0.02mm due to guide piece

- Hardened, ground stainless steel shafts also for abrasive environments

- Hard anodized, high-strength aluminum

- Holder for clamping inductive proximity switches

- C-slots for accommodating magnetic field sensors

- Grid dimension for a precise, backlash-free centering system for installation without drilling or pinning

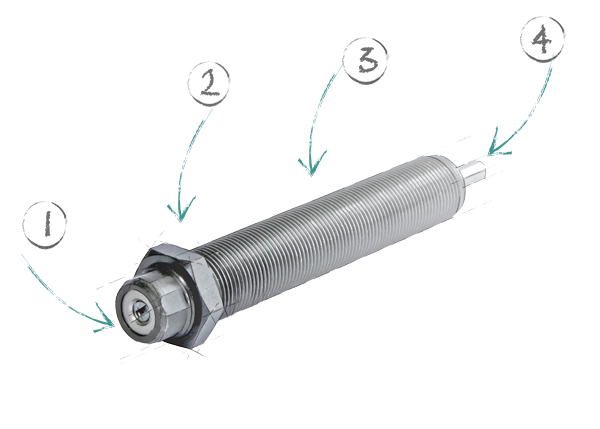

Accesories

Shock absorber STD-14

- Adjustment screw for changing the degree of damping

- Hexagon nut for locking the damper

- Threaded sleeve M14x1, Tenifer® treated

- Piston rod, stroke 12mm, retracts flush