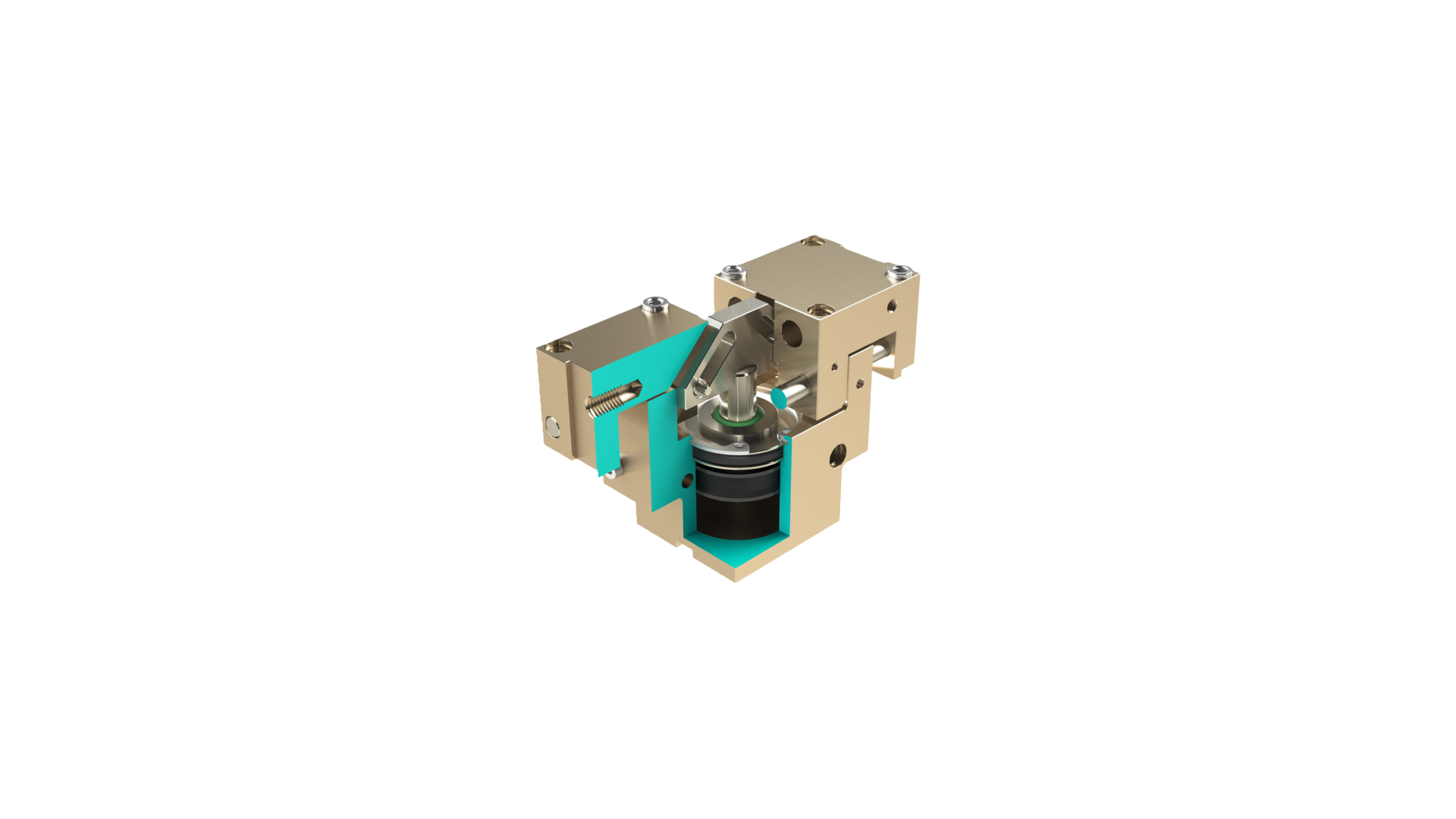

Animation: technical principle of parallel-gripper PGM

Parallel grippers of the PGM series from Friedemann Wagner enable precise and reliable handling of objects in automated processes.

The functionality and technical structure are kept as simple as possible:

The PGM parallel gripper is pneumatically operated. Compressed air moves the piston. A deflection piece generates a movement that opens and closes the gripper jaws.

The PGM's jaws are designed to move parallel to each other. This means that when the gripper jaws close, both move simultaneously and steadily toward the object, ensuring even force distribution and a secure grip.

The jaws are mounted in the deflection piece . They are securely guided on ground, stainless steel guide shafts on the left and right sides. This provides the necessary rigidity to absorb tilting moments during the gripping process.

If you are interested, you can find further information on the technical structure (with cross-sectional drawing) in this blog.

To ensure safe and efficient gripping, all PGM models can be equipped with proximity switches (sensors). These acknowledge the position of the gripper jaws and, when correctly configured, monitor the "open" | "closed" | "gripped" states.

This ensures that the object is correctly recorded in the automation process.

For more information on querying with sensors, see this blog .

Like all pneumatic actuators from Friedemann Wagner GmbH, PGM-type parallel grippers are easy to install with centering rings (fits), threaded holes, and locating holes. To facilitate the installation of specific gripper fingers, four additional centering rings are included.

Downloads

NOTE: OUR DOWNLOADS ARE MAINLY AVAILABLE AS PDF FILES. YOU WILL NEED THE LATEST ADOBE ACROBAT READER TO READING THEM.

Parallel gripper

The simple and reliable design of PGM offers versatility in the use of various applications from assembly and packaging to handling of workpieces in production.

The technical data given for PGM apply at 6 bar, whereby the PGM parallel grippers can be operated between 2 and 8 bar !

Maintenance tip: the open, always centering design allows blowing out and lubrication while installed.

Technical data, the 3D model as well as links to the brochure and operating instructions can be found directly in the product selected below.

Further information can be found in the central download area , under the FAQ section, our blogs or our YouTube channel.

We look forward to hearing from you

Personal advice

Friedemann Wagner GmbH

Robert-Bosch-Str. 5

D-78559 Gosheim

+49 (0) 7426 / 949 00 -0

+49 (0) 7426 / 949 00 -9

Write an email