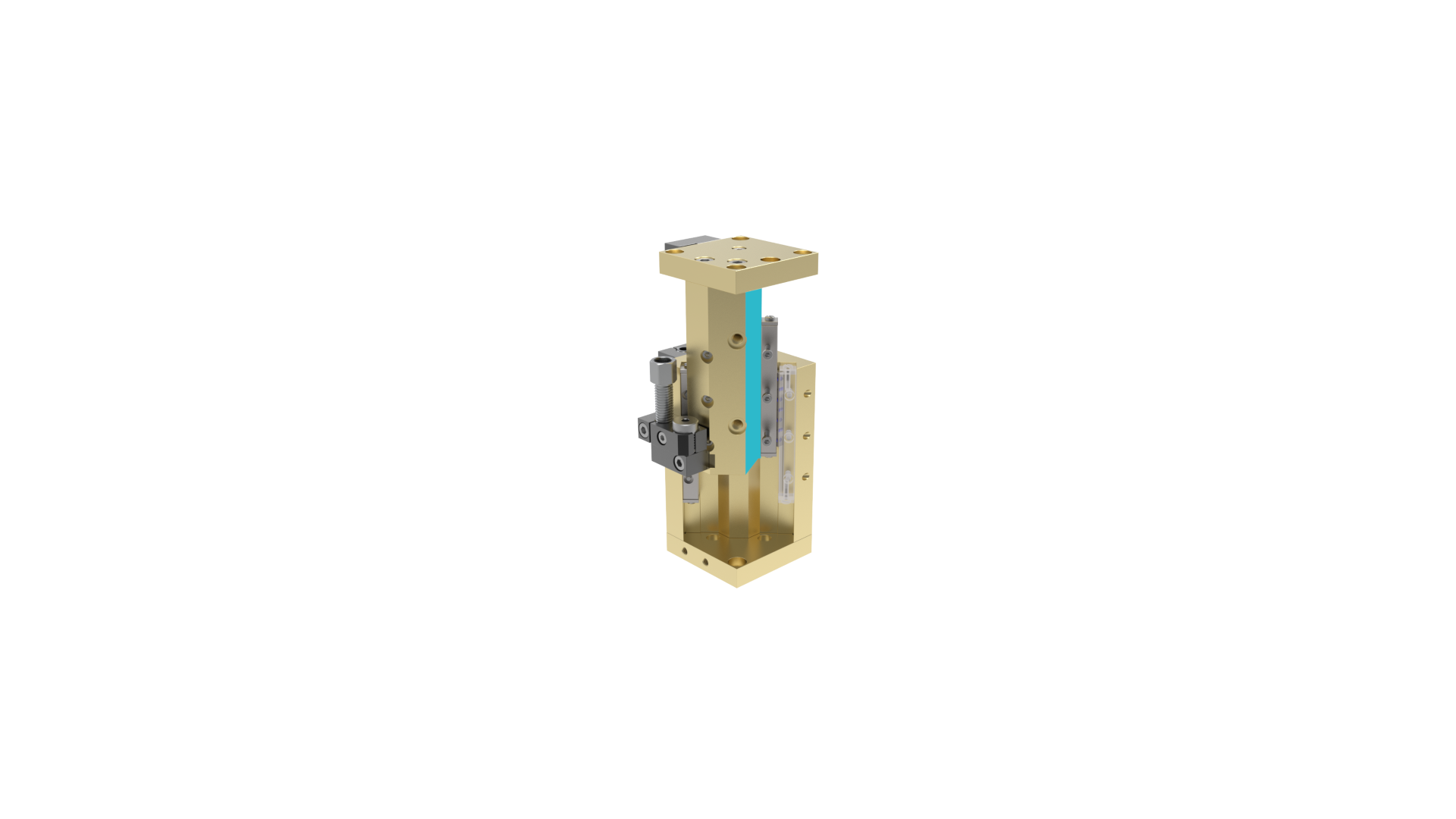

Animation: technical principle of lifting-unit with cross-roller-guides

Summary

Lifting units are pneumatic actuators. They are linear modules, specifically designed for pneumatic lifting (vertical operation). A high-strength aluminum housing, robust design, and high rigidity are the foundation for use in automation-engineering. The unit itself can be fixed using a centering system. Using the grid of centerring-rings upside, e.g. a rotary actuator can be mounted on top of the lifting unit - easy and fast assembly!

downloads

NOTE: OUR DOWNLOADS ARE MAINLY AVAILABLE AS PDF FILES. YOU WILL NEED THE LATEST ADOBE ACROBAT READER TO READING THEM.

pneumatic lifting unit

Technical data, the 3D model as well as links to the brochure and operating instructions can be found directly in the product selected below.

Further information can be found in the central download area , under the FAQ section, our blogs or our YouTube channel.

We look forward to hearing from you

Personal advice

Friedemann Wagner GmbH

Robert-Bosch-Str. 5

D-78559 Gosheim

+49 (0) 7426 / 949 00 -0

+49 (0) 7426 / 949 00 -9

Write an email