screw-in column for rotary-indexer

What is the benefit of a screw-in-column for a Wagner-rotary-indexer?

Pneumatic driven rotary indexers from Wagner do convert a linear transition of a piston (gear-rack) into a turning table rotation, using a pinion.

They are in active use in different partitions and turning directions in numerous automation applications.

The screw-in-column is like a central tripod and can be the mounting-place for additional modules.

It enables engineering-departments to easy install further elements above the turning disc.

Make the most of valuable space by compact compilation of modules.

It is irrelevant, if additional elements really are to be fixed immobile or e.g. further pneumatic modules are mounted by using a clamping piece (accessories) to handle on the workpieces on the rotating disc.

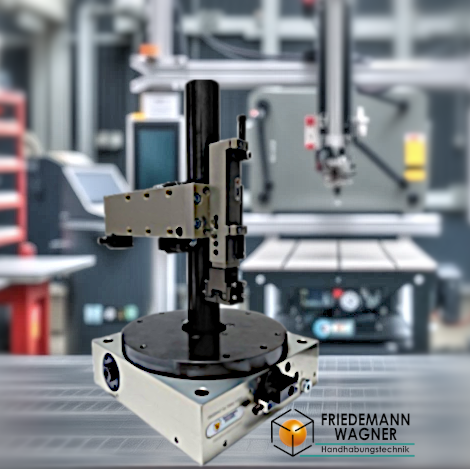

Exemplary Trade Fair Setup

See for yourself at our trade fair appearances how we can compactly, quickly, easily, and effortlessly mount various handling units above a rotary indexing table. As shown in the image on the right, a horizontal linear unit LSK-4 and a vertical linear unit LSM-3 with a directly mounted mini gripper PGM-29 are attached to the screw-in column of the RSE-6 rotary indexing table using a clamping block. For further information, you can download the Wagner modules used as an STP file via the following link! You will immediately see what our modular system makes possible. As shown here in the blog, grid dimensions and centering rings (fits) form the basis for fast, drill-free assembly.

You are interested in an example?

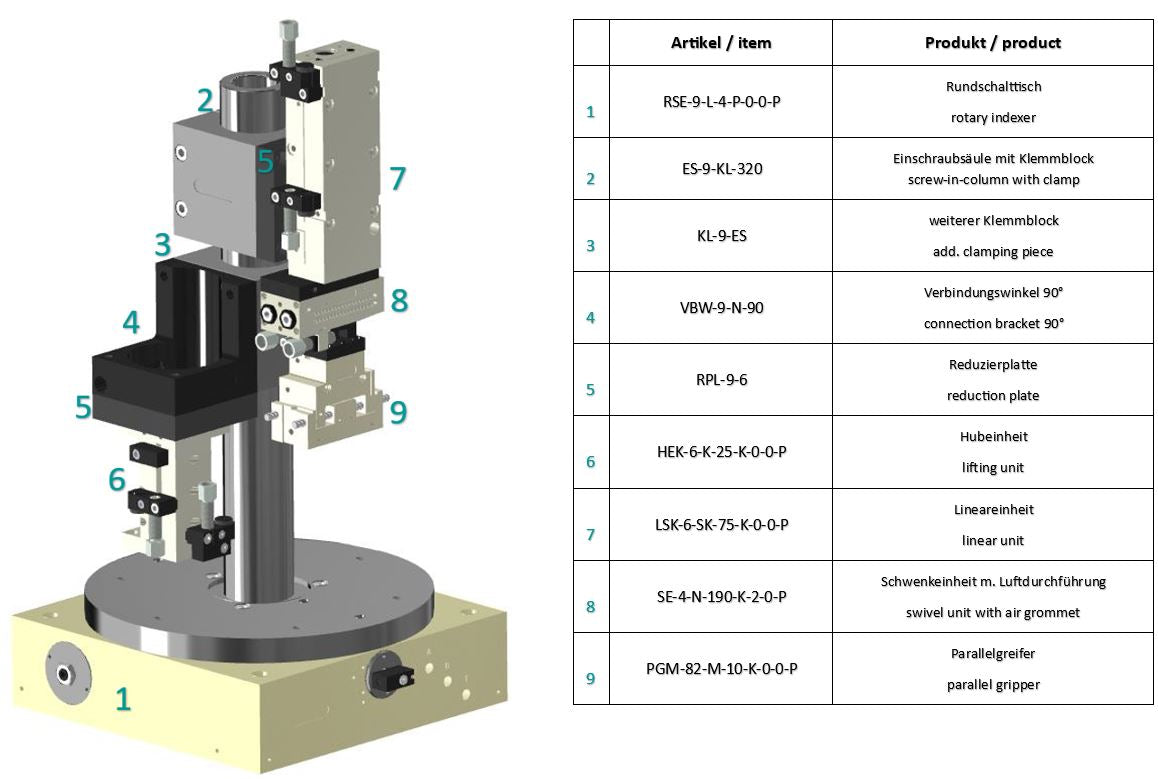

See following words, the 3D-picture and the listing of items

Task:

A rotary indexer RSE-9, turning direction ccw, partition 4 and pneumatic damping shall be loaded on position 1 and unloaded at position 4.

Inbetween, the workpiece e.g. shall be joined with another item at position 2.

Position 3 lifts the workpieces to change their angle via 90 ° for the following "unloading" position.

Solution:

A lifting unit HEK-6 can be mounted directly to the screw-in column using a clamping bracket and adapter element. Pressing takes place at this position 2.

The plate continues to move after activation.

A linear unit, whose stroke acts in the Z-direction, is fixed to the screw-in column's top-mounted clamping block using an LSK-6. A SE-4 rotary actuator (adjustable 0-190°) with a PGM-82 parallel gripper is mounted top-down on the front plate of the linear unit.

The swivel unit is equipped with air grommets, to enable feeding the air for the gripper through the turning shaft!

This unit therefore moves down to position 3, grabs the workpiece and turns it according to the task!

Keep in mind: As the screw-in-column is a hollow shaft, named upper modules can be supported via the center!

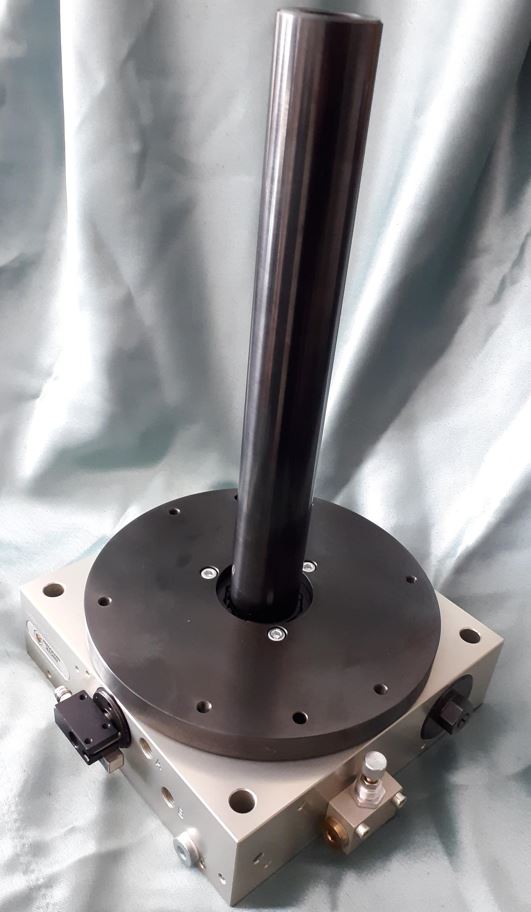

Installation or retrofit- how to

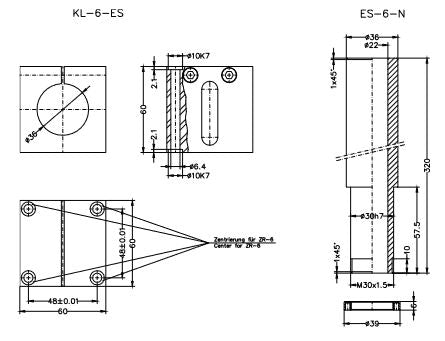

Both technical related rotary indexing tables RSE-6 und RSE-9 do have a fix center hole (fitting). The center of the table (disc) has a plastic-cap in the middle - simply to squeeze out.

Footer of ES-6 und ES-9 also are fittings. They are just brought in the center-hole and countered -from below- with a threaded ring.

A great benefit in installation and use, as the complete unit is portable! The column has not to be placed in one fix location of the application.

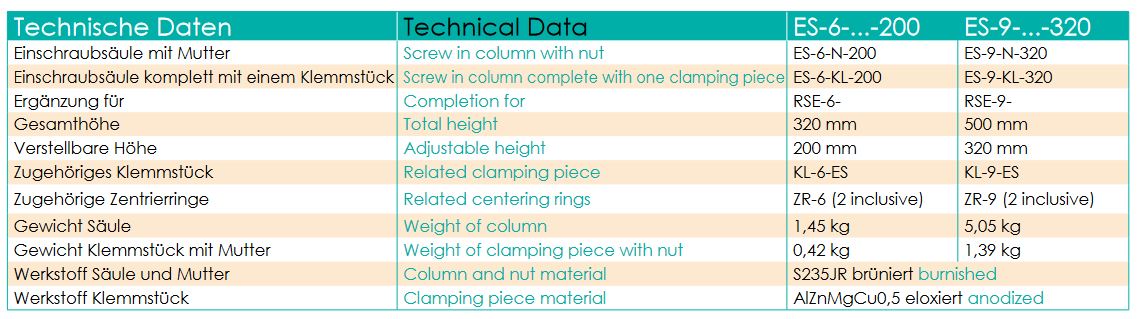

Interested? Please check datasheet of the column for further information.

Faster than reading - short video in German language (turn of speaker):

What is the benefit of a screw-in-column for a Wagner rotary indexer