Swivel units of Friedemann Wagner GmbH Handhabungstechnik have an external stop-system – enabling the user to detect a defect shock absorber in time.

External stops provide full force in the final position, as the drive-torque is the same as the stop-torque.

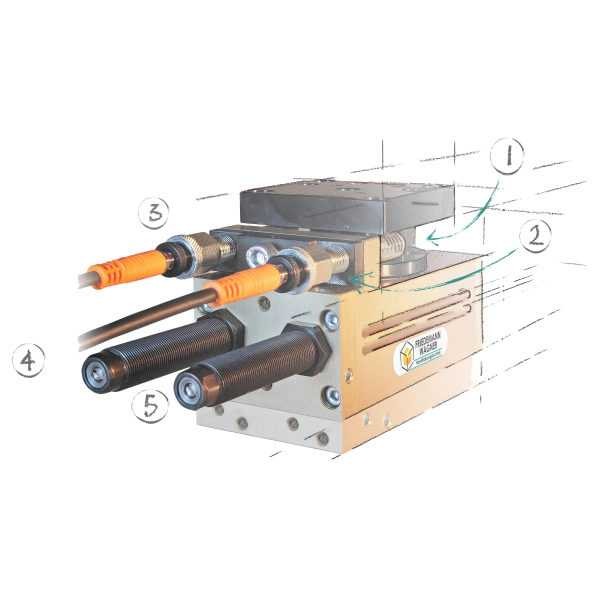

The toroidal areas (1) lead to essential (repeat-) accuracy. A patented stop-system (2) defines the angle of rotation (190°) by screw-in our screw-out. To fix the stop-screw-system a plate counters them. At the same time these hollow screws are the place to insert the proximity switches via a threaded bushing (3). The sensors can be aligned even a few hundredths of a millimetres, to exactly confirm the end-position. A knurled nut fixes axial positioning of the proximitive switch. Even though: the sensor itself still stays pivoted just to make the use of angle-connectors easy.

All interfering edges are on one side of the system (4). As the end-position is exactly monitored, a PLC-query can detect a defect shock absorber (5) as bouncing. The application can be stopped in advance of expensive costs. Die robust construction principle separates drive from stopping position – in case of a broken dampers incorrect loadings are avoided.

Elaborated rotatory power-packs from a manufacturer with more than 36 years experience in the market. Handling units in different sizes and in modular design – also availabe with air and signal grommets – bring valuable benefit to your application.