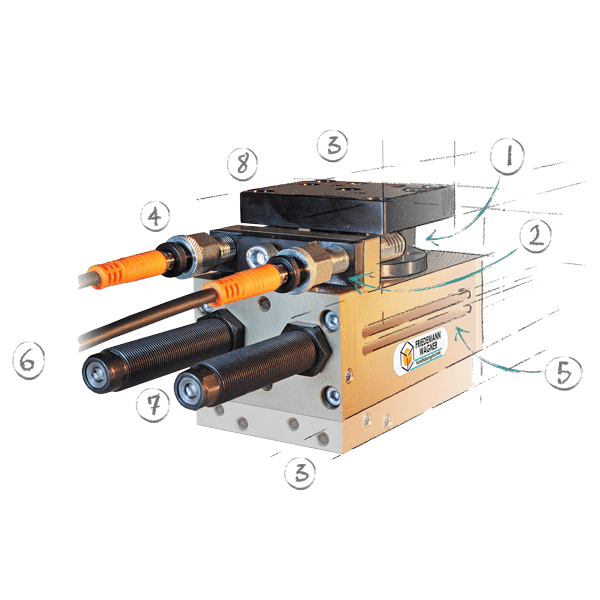

- External stop system of the swivel unit ensure high repeat accuracy on toroidal stop areas and full torque in the end-position. The gear is unloaded and therefore irrelevant for accuracy or positioning.

- Stop-screws for continuous adjustment up to 190° (+/-95° from center). Adjusting and fixing of rotation angle of the swivel unit is enabled from outside. The screw-recess is part of the high-strength milled aluminium housing, any tolerances by mechanical joining are therefore eliminated.

- Air- and signal-grommets are available in swivel units as product-variants. Supply of the upper structure can be done through the turning shaft to avoid torsion and to enable short distances.

- Patented system to attach the proximity sensor inside the stop-screw. The switching point can be adjusted by screwing the sensor further in or out to allow monitoring of the defined stop-position (see monitoring of declining shock absorbers). As it will be countered (knurled nut) the position in relation to the screw is kept –this is helpful and saves time during installation.

- Gear shafts are fitted with magnets – as an option cost-effective magnetic- field-sensors can be used inside the C-slots.

- All connections and extending measurements are single-sided. Accessibility during installation is easier and effective. Furthermore

all other sides can be used in your application to save valuable space around the swivel unit. - Input for hydraulic shock absorbers in case of high moments of inertia up to 64200 kgcm2.

- Grid dimension for accurate-fitting center-system, for mounting other products free-of-play – without drilling or pinning.