NEW - manually driven Wagner rotary indexer RSE-6-M!

You are right! Wagner launches a new product beginning 2023 - a manually driven rotary indexing table. Why manually driven?

Apart from classic hand-assembly-places with e.g. several different rotating stations, there are a lot of possibilities to support your production-staff!

Remember the relief in case of turning a heavy workload (e.g. a transformer or other coiled goods). Or think about a manually assembly station followed in sequence by a fully automated testing-process.

Another idea: handle over of goods with additional buffering to a COBOT!

Or just in case your mechanical constructon department is looking for a simple, reliable, cost effective solution - without time-consuming topics like security-technologies, drive, control, installation etc..

The patented rotary indexer is self-locking. After the turning is done, indexing takes place in end position - backlash-free. If work is done in that position, unlocking is started with a pneumatic pulse (3/2 valve). Next turning starts manually to the next partition.

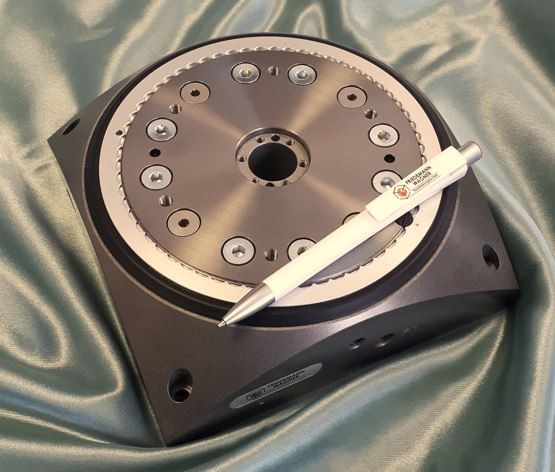

As manually operated: The rotary indexing table is rounded (see image).

Turning direction and partitions can be ordered as different variants. One conversion-kit (accessories) allows the user to change the partition later on! Even turning direction is changeable!

This allows a flexible use in different applications - a protection of investment.

Enclosed please find a table as an overview to some technical features of the manually driven rotary indexer:

| feature | value | note |

| Accessories | yes | conversion kit partitions |

| Axial load dynamic [N] | 250 | ! check moment of inertia and turning times ! ca. 25kg @ D=140mm |

| Axial load static [kN] | 4 | static stress @ Ø140mm, e.g. press-in on the table |

| Dimensions[mm] ca. | 180x180x62 | |

| Drive | manually driven | indexing backlash-free (patent) |

| Direction of turning | right/left | tell when order, changeable by user |

| Fixing of table | centering ring | 2x ZR-9, scope of delievery |

| Fixing of workload | threaded holes | 6 xM6 je 60°, in the plate @ D=109mm |

| Fixing of workload | fitting holes | 2 x5H8, in the plate@ D=109mm |

| Fixing of workload | fitting hole | 1 x35H8, centric |

| Dampers | no | |

| Direction of use | any | four point bearing |

| Material housing | aluminium | hard anodized |

| Material plate | steel | galvanized |

| Monitoring end-position | yes, accessories | proximity switch NSI-M8-S55 or NSI-M8-K50 |

| Moment of inertia [kgcm²] | 20.000 | max. see instruction manual |

| Partitions | 2/3/4/6/12 | tell when order, changeable by user |

| Product weight [kg] | 5,8 | |

| Tilting moment [Nm] | 300 | |

| Unlocking | pneumatic | 3/2 valve, not included |

Technical data and drawing can be seen in this brochure-link.

3D-Data can be downloaded when selecting the model in the productfinder.

In case of interest please feel free to use our contact-sheet.