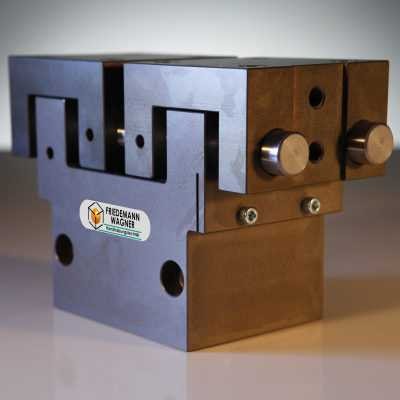

Our well known parallel-grippers (PGM 120 und PGM 140) are available in special versions – off the shelf!

The centrally positioned guiding element, moved via the piston, has been changed in its gradient. This enables higher forces for spreading (variant „Ö“) or clamping (variant “S”).

This is why recommended payloads (force-fit) are increasing upon additional 50% – in relation to complementary standard variant.

The wide guiding principle, based on two grinded stainles stell shafts, the system PGM is extremely solid and competes with tilting effects to deliver a precise use.

The central positioned guide-piece is routed in housing and jaws end enables repeatable consistancy in centerring. Even in case of heavy wear, the jaws will be placed back in the middle. The tough surface (hard coated) is durable and proves +/-0,02 mm repeat-accuracy-precision.

The open principle of the pneumatic grippers provides easy maintenance: air-cleaning or lubrication can be done in mounted position.

| PGM | clamping force[N]* | spreading force [N]* | stroke / jaw [mm] | type |

|---|---|---|---|---|

| PGM 120 N | 380 | 405 | 12 | PGM-120-N-12-K-0-0-P |

| PGM 120 S | 630 | 405 | 12 | PGM-120-S-12-K-0-0-P |

| PGM 120 Ö | 380 | 655 | 12 | PGM-120-Ö-12-K-0-0-P |

| PGM 140 N | 650 | 685 | 15 | PGM-140-N-15-K-0-0-P |

| PGM 140 S | 1050 | 685 | 15 | PGM-140-S-15-K-0-0-P |

| PGM 140 Ö | 650 | 1090 | 15 | PGM-140-Ö-15-K-0-0-P |

Einsatz der Parallelgreifer PGM zwischen 2 und 8 bar möglich – Angabe technischer Werte bei 6 bar !