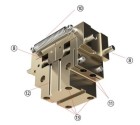

- Pneumatic piston (1) moves

- guided element (2) via

- hard chrome plated piston-rod (3) direct to

- diverter (4) (material: X45NiCrMo4)

- jaws (5) are restrained guided (6), a gradient brings piston-movement to open / close of jaws

- the diverter also is guided in a channel (7) inside the jaws

- to handle tilting moments, both jaws are guided on smoothed stainless hardened shafts (8)

This principle of construction always leads to a centering position of the gripper!

You are right: it is possible that dirt enters the open system, but for sure the dirt also is enabled to easy leave the open system!

So dust e.g. will not stay inside and blockes the gripper! And the gripper can be blown-off and lubricated in mounted position!

The piston-rod is guided in a wiper-ring (9) to avoid dust reaching the piston itself!

The chosen and already named materials, as well as the hard-coated high-strength aluminium of housing and jaws do grant long-life persistence.

Due to space issues, only some variants are available with clamp- and spreading force retention (10) by springs.

All products do have clamps for mounting inductive sensors (11).

Via blind-holes in the jaws, it is possible to monitor the status:

- open

- closed

- payload gripped

As it is a small, compact construction-volume the shown c-slot-sensors (12) only are available from size PGM-60 upwards.

Variants of PGM can be ordered in different sizes from 2 mm up to 15 mm stroke each jaw. Repeat accuracy is +/-0,02 mm.

Maximum recommended payload depends on the size (piston -diameter 10-63 mm) and has a range of 0,13 kg up to 7,2 kg – force-fitted .

Length over closed jaws gives the product name e.g. PGM-29 means: both jaws (in closed position) do measure 29 mm.

Technical data are valid at 6 bar, but parallel gripper PGM can be used from 2 up to 8 bar . This maybe is interesting for very small or heavier payloads.

Using external air restrictors enables you to adjust speed.

All grippers include 6 centering-rings. These fittings (h6) help to assemble the fingers and the grippers

itself via the corresponding bore-holes (13).