Evidence of sustainable and durable products - no common or modern slogan!

We have to admit: as Swabians we do have an obligation by birth: be frugal and save ressources.

We, at Friedemann Wagner GmbH, are manufacturer of exact and durable products!

due to our vertical integration we also offer refurbishments (e.g. longtermed duty), repairs (e.g. after crash) or retrofit (e.g. change partition from 8 to 12 on a customers elder Wagner-rotary-indexer).

Our on longevity based construction together with used durable materials, we keep your invest alive! For a long time! This is sustainability - for you and us!

Please check some random cases of our internal documentation - each device is noted and marked when returning to us!

| productgroup | product | manufactured | revised | scope of revision |

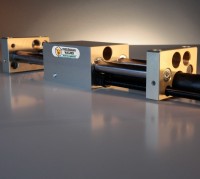

| linear unit | VEN-6 | 2001 | 2019 | shock absorber, guide shafts and bush-bearings, stop-element, VSTS*; KT** |

| swivel unit | SES-6 | 2004 | 2020 | shock absorber, bearing, connector and cable, VSTS, KT |

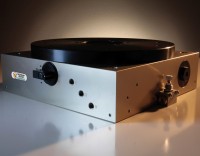

| rotary indexer | RSE-3 | 2005 | 2020 | defect shock absorber lead to broken piston and pinion , VSTS, KT |

| rotary indexer | RSE-6 | 2001 | 2020 | indexing-bolt worn, locker, damping cover, piston, stop-element, VSTS; KT |

| linear unit | LEK-6 | 2015 | 2021 | revision by customers´ wish - retrofit of its applicaton, shock absorber, air tube, VSTS KT |

| rotary indexer | RSE-4 | 2014 | 2021 | pinion and piston gear damaged due to crash, bearing, shock absorber changed, VSTS, KT |

| lifting unit | HE-6 | 2010 | 2021 | revision driven by customers´ wish: new guide shafts and bush-bearings, piston, VSTS, KT |

| rotary indexer | RSE-6 | 1998 | 2021 | gearsegment changed as worn (gaps), locker, piston an indexing-bolt renewed, shock absorber, VSTS, KT |

| rotary indexer | RSE-9 | 2012 | 2021 | restrictor leakage, locker, indexing-bolt worn, shock absorber, piston, VSTS, KT |

| rotary indexer | RSE-6 | 2000 | 2022 | locker, indexing-bolt, piston, shock absorber, VSTS, KT |

*VSTS = set of wear parts (e.g. static and dynamic seals etc.)

**KT = small parts, screws, hex-nuts.

Are you aware of? Even our own shock absorber STD-14 can be revised!

What´is the procedure for revisions?

You send back your item - in best case with extensive description.

Inbetween 3-5 working days after arriving you´ll get an offer for the revison, if it does make sense from an economic perspective!

After your decision to "order" the revision: most often 10 working days later the product is leaving us.

Most often? Products do change technically (inside) over the timeline.

So if yo send back "elder" products we maybe have to manufacture / procure some parts!

Periodic maintenance does help!

Lifetime of products can be extended by periodic preventive maintenance.

btw: Your maintenance-team also can do a revision on your own - our spare-parts-lists are online!

We have come full circle: our operating instructions shows maintenance recommendations on time periods and (impressing) cycle numbers!

| produktgroup | produc | direct link |

| rotary indexing unit | RSE-3 / RSE-4 | page 38 chapter Maintenance |

| rotary indexing unit | RSE-6 / RSE-9 | page 39 chapter Maintenance |

| swivel unit | SE / SES / SHE | page 44 chapter Maintenance |

| lifting unit | HE / HEK | page 36 chapter Maintenance |

| gripper | PGM | page 32 chapter Maintenance |

| linear unit | LSM / LSK | page 37 chapter Maintenance |

| linear unit | LE / LES / LEM / LEK | page 44 chapter Maintenance |

| linear unit | LEN / VEN / ZWP | page 41 chapter Maintenance |