Energy efficiency, as rotary indexer RSE-6-M is manually driven?

Not only - but in general: as semiautomated workplaces are slready cycle-influecend by human beings, why to use energy for drive?

There is a bit more ...see following advice:

What about the idea to do a fast manually pneumatic unlocking? Hence using only the amount of pressured air (energy) that is needed to unlock the system and enable further turning.

Technical view:

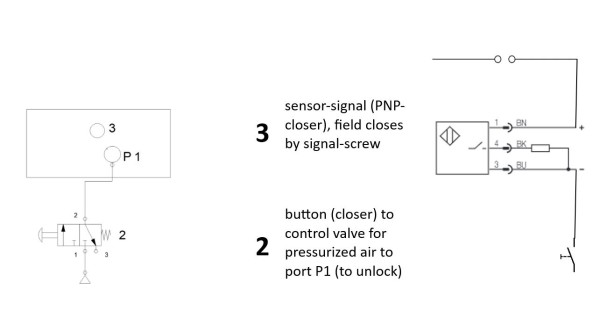

Wagner-rotary- indexing-table "RSE-6-M" locks automatically in end-position. For the following turn a pneumatic unlocking is done. You therefore need a simple 3/2 control valve, spring-return, manual released - see link to assembly and operating manual.

Now the Swabian heart awakes ...

The longer the user is pressing the "unlocking-button", the more pressurized air is needed ...although the unlocking process itself only needs a very short impulse!

When using the function monitoring the endposition via sensor, you know that on bottom of the disc signal-screws are located each partition-position. They close the electric field of the inductive M8-screw-in-sensor. When locked, the proximity switch gives signal.

If sensor-signal is in a row with the manual release, the circuit now is closed and air is given to port P1.

Within the patented principle of RSE-6-M the pneumatic unlocking leads to a unlatch impulse - the disc gets a short kinetic push towards turning direction.

That means, the signal screw moves away from the proximity switch and opens the circuit - pressurized air will be stopped.

Interesting? Please use our enquiry-sheet, if you like to get more information on RSE-6-M!

Much faster than reading: here you ´ll find a short video of the fair exhibit - manually driven rotary indexer "RSE-6-M" by Friedemann Wagner GmbH.