2019 45 Years handling products from Friedemann Wagner

Many thanks to all our customers and partners!

See product-benefits here...

2015 decision „Start with our own sales“

2013 Management of the company is passed inside the family to grant continuation of the company in the second generation

2006 solution provider for customized and related products outside of the existing standard portfolio (OEM)

1991 move to the newly built business premises (management and manufacturing)

1990 new company building in the industrial area of Schwellbach, for space and capacity reasons on a large plot for future expansion

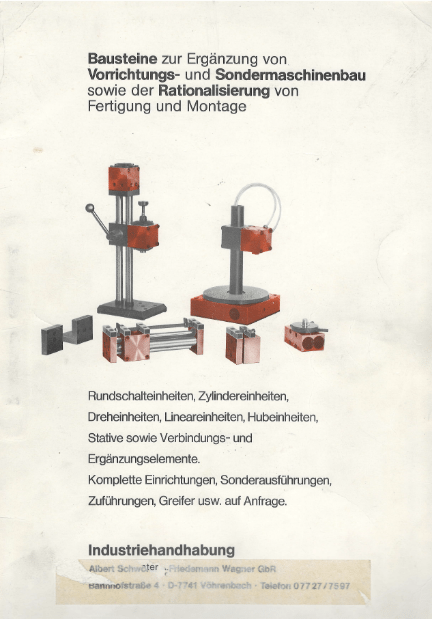

1986 establishment of Friedemann Wagner GmbH, industrial handling technology

1984 moving of the company

Exclusive sales of our products by a well-known pneumatic distributor

1981 continuation of the company by Friedemann Wagner as GbR

1979 founding as Albert Schwörer - Friedemann Wagner GbR located in 78147 Vöhrenbach

Goals of the founders

Sector: Industrial handling and automation technology

Product idea of founders

Goal of the founders: to design, manufacture and offer handy, modular and practical industrial handling units for automation.

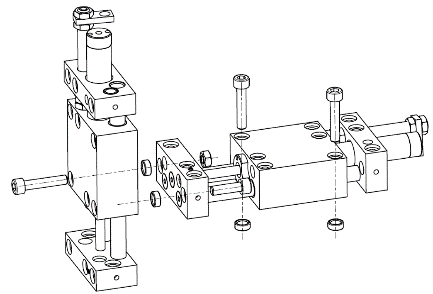

Basic idea was an expandable modular system of quickly, easily, and accurately mountable pneumatic industrial handling devices.

Product benefit definitions:

- Modularity with easy-to-set aligned grid dimensions

- Fast, easy installation of the units with each other

- Reliability

- Accuracy

- Precision

- Accuracy in repeatability

- Durability

Implementation

At that time 2 (today 4) compact sizes had been designed in grid dimensions as a kind of cube form and are directly matched to each other – modularity as an integral part of the product.

The first brochure already pointed out the modularity of the system in its headline:

“Handling components for special-purpose machinery as well as for rationalization of manufacturing and assembly”.

The founders´ high aims: simple, fast and yet precise assembly of components with each other. Solved by their own development and design of a centering system by centering rings and grid arranged through- and threaded-holes.

The founders´ high aims: simple, fast and yet precise assembly of components with each other. Solved by their own development and design of a centering system by centering rings and grid arranged through- and threaded-holes.

In addition to translational solutions, rotary handling tasks have been fixed as a special goal for the company’s founders.

The swivel units, former named as “rotary units”, already had easy-to-set external stop-systems. The product range already included a very compact, square built rotary indexing table whose side length corresponds to the diameter of the turntable. This table had a fixed middle hole – ahead of its time! A special feature for the space-saving implementation of energy lines or just to mount and fix different handling-tasks in the middle.

In the document to obtain patent application and/or utility model protection, the wording of the patent attorneys from 28.05.1980 is as (translated) follows:

In the document to obtain patent application and/or utility model protection, the wording of the patent attorneys from 28.05.1980 is as (translated) follows:

“The table of the rotary indexing unit revolves around fix hollow center axis, while with all other known rotary indexing units the central axis rotates with the table. This has the advantage that in the fix center a solid or hollow column can be placed to which additional elements or devices can be mounted. With all other known rotary indexing units all additional devices need to be arranged on outside mounted stands, what is more complex and requires more space.”

translated quote from the letter of the patent attorneys Dipl. Ing. Westphal, Dr. Mussgnug and Dr. Buchner